Unique screw technology, advanced temperature control and long service intervals

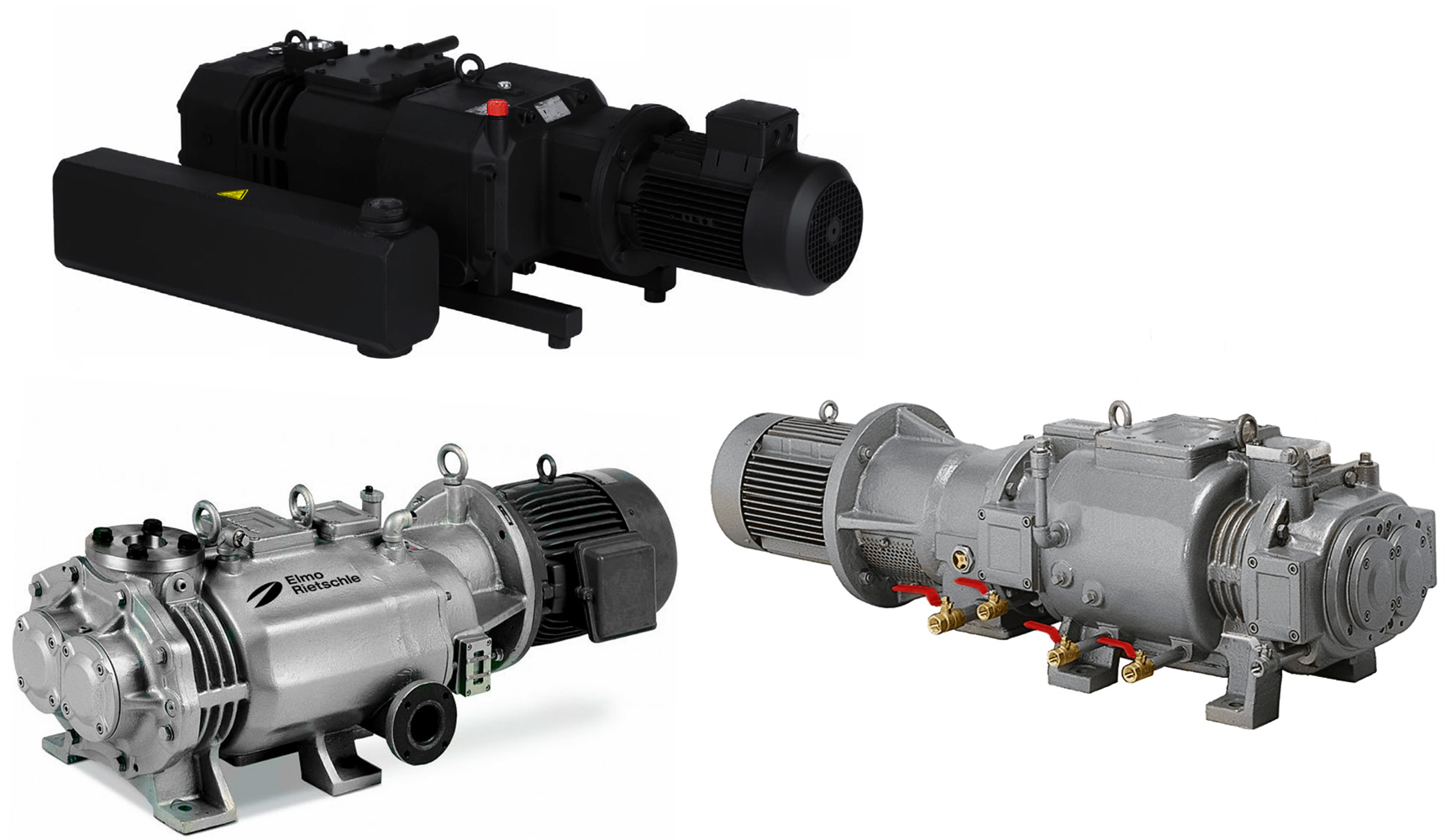

The EXS series dry screw vacuum pumps have been developed as a single unit, designed for simplicity and robustness. With more power, simple control philosophy and low maintenance costs, the EXS offers reliable performance.

EXS screw vacuum pumps can be used in a variety of applications including:

- vacuum brazing

- electron beam welding

- nitrocarburizing

- low-pressure nitriding

- low pressure carburization

- carbon vapor impregnation

- sintering

- metal powder injection molding

- precision investment casting

- vacuum arc finishing

- plasma welding

- plasma nitriding

- space simulation chambers

- Gas recovery/recirculation

- lock chambers

- silicon crystal pulling

- photovoltaic lamination

- Roller and coil coating

- Hard Coating (CVD/DLC)

- surface activation

- plasma coating

- glass coating

ECONOMICALLY – Affordable capital investment and low operating costs

- Significant savings: low utilities and energy usage costs

- Space-saving: small footprint

PROVEN – Based on existing GXS technology

- Huge install base: on hundreds of applications

- Streamlined Design: Enables improved performance

ENVIRONMENTAL PROTECTION – Smooth, quiet running with low power and energy consumption

- Low carbon footprint: low power consumption and use of utilities

- Environmentally friendly: no pollution or dirty disposable oil

FAST – Increased roughing speeds and low

ultimate performance

- Increased productivity: faster processing and pump down times

- Low ultimate pressures <1 x 10-2

ROBUST – Reliable operation even under harsh conditions in industrial applications

- Low maintenance costs: no unplanned downtime

- Increased productivity: longer intervals between duty

Page 1 of 1

EXS 750 screw vacuum pumps

| Designation | Value |

|

| ultimate vacuum | < 1x10-2 mbar | |

| pumping speed max | 740 m³/h | |

| final performance | 8k | |

| full load performance | 22kW | |

Page 1 of 1