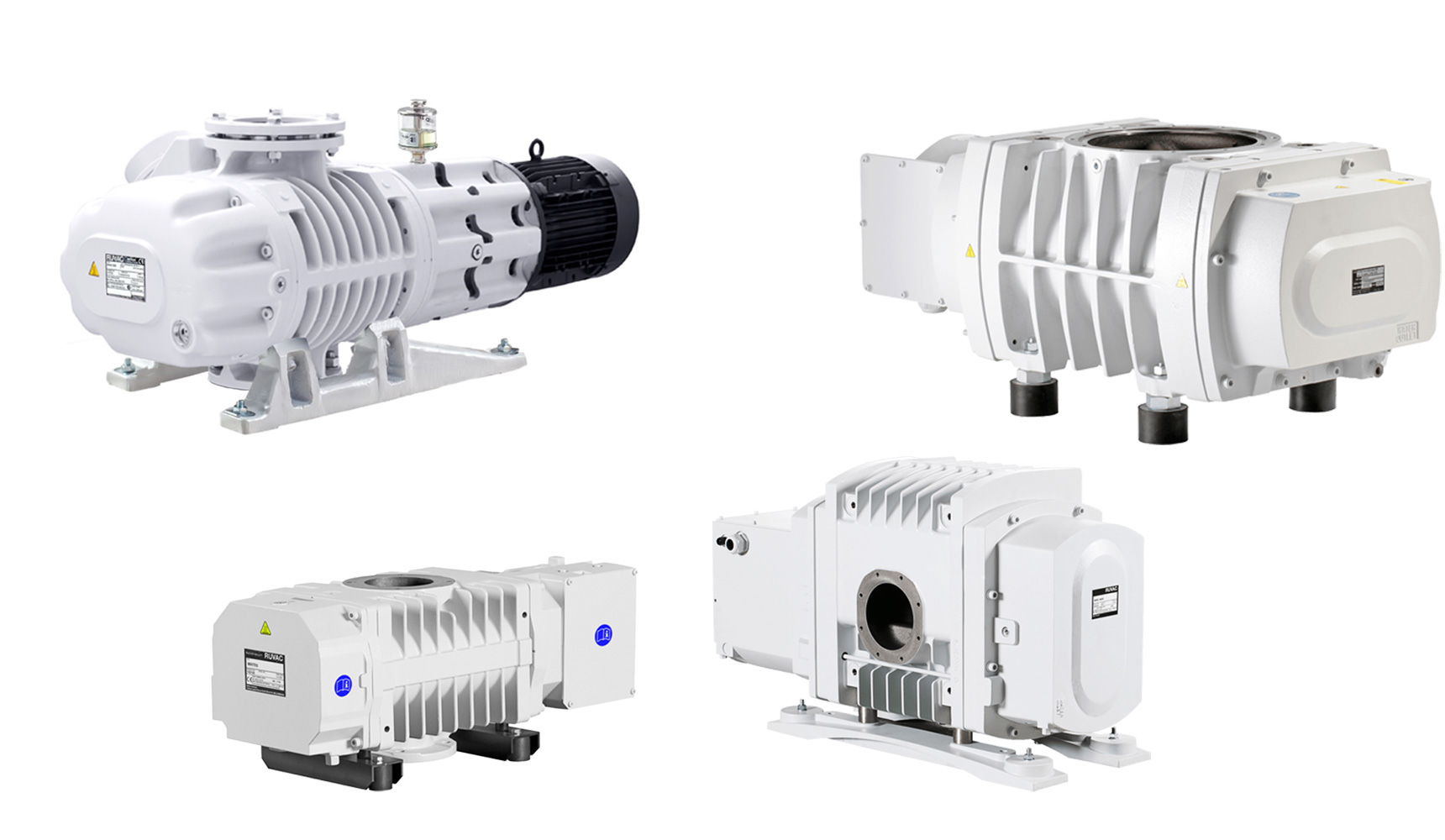

RUVAC WA / WAU

The RUVAC WA Roots dry-compressing vacuum pumps are pumps in which no lubricant comes into contact with the medium to be pumped and therefore the vacuum created cannot be contaminated by hydrocarbons. The seals are made of FPM.

RUVAC WS / WSU

The Roots vacuum pumps of the RUVAC WS series are driven by air- or water-cooled canned motors. An optional frequency converter is matched to the pump in such a way that mechanical overloading is ruled out. If the pressure difference is too great, the speed of the pump is automatically reduced until its load is within the permissible range. The RUVAC WSU variants are also equipped with an integrated pressure compensation line and a pressure difference valve. The pumps in this series are delivered with a vertical pumping direction as standard.

RUVAC WH / WHU

The RUVAC WH / WHU series is equipped with a hermetically sealed motor without shaft seals and with integrated water cooling. It also has a purge gas option and is therefore suitable for conveying corrosive and toxic gases. The RUVAC WHU model variants also have an integrated detour line with a newly developed control flap. This means that the pumps can be started at atmospheric pressure and the pump-down times in the short cycle are significantly reduced.

Benefits for the user

RUVAC WA/WAU

RUVAC WS/WSU

RUVAC WH/WHU

Page 2 of 2

RUVAC WHU 2500 vacuum pump

| Designation | Value | |

| frequency | 50Hz | 60Hz |

| nominal pumping speed | 2500 m³/h | 3000 m³/h |

| Max. allowed pressure difference | 160 mbar | 160 mbar |

| rated power consumption | 15.0kW | 18.0kW |

RUVAC WHU 4400 vacuum pump

| Designation | Value | ||

| frequency | 50Hz | 60Hz | 80Hz |

| nominal pumping speed | 4400 m³/h | 5280 m³/h | 7040 m³/h |

| Max. allowed pressure difference | 120 mbar | 120 mbar | — |

| rated power consumption | 11.0 / 15.0 kW | ||

RUVAC WHU 7000 vacuum pump

| Designation | Value | ||

| frequency | 50Hz | 60Hz | 80Hz |

| nominal pumping speed | 7000 m³/h | 8000 m³/h | 9800 m³/h |

| Max. allowed pressure difference | 60 mbar | 60 mbar | — |

| rated power consumption | 11.0 / 15.0 kW | ||

Page 2 of 2