ROOTS VACUUM PUMPS

Roots vacuum pumps, also known as vacuum boosters, are among the dry-running vacuum pumps that, together with backing pumps, cover a wide range of applications in which high pumping speeds are required. Vacuum boosters work completely contact-free and without sealing liquids such as oil or water in the working chamber, although in most models the two gear wheels of the synchromesh and the bearings for the impeller shaft are lubricated with oil. Some of the pumps are equipped with a by-pass valve.

The advantages at a glance

- Robust and economical

- Dry running

- Modular design

- Reliable and resilient

- Available as individual aggregates

- Comprehensive range of accessories

- Frequency control possible

Application examples

industry in general

- extraction systems

- drying

- ventilation

- various process engineering applications

- vacuum conveying

environmental engineering

- extraction systems

- ventilation systems

- drying plants

- gas circulation

- domestic sewage treatment plants

The advantages at a glance

- robust and economical

- running dry

- modular design

- reliable and resilient

- available as individual aggregates

- comprehensive range of accessories

- Frequency control possible

Application examples

industry in general

- extraction systems

- drying

- ventilation

- various process engineering applications

- vacuum conveying

environmental engineering

- extraction systems

- ventilation systems

- drying plants

- gas circulation

- domestic sewage treatment plants

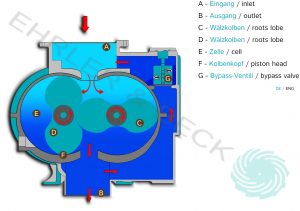

operating principle

The individual Roots vacuum pumps were designed for use in aggregates in combination with a rotary vane pump as a variable pump. The functional principle of Roots vacuum pumps or vacuum boosters is very similar to that of rotary vane pumps. Through the entrance (A) air flows into the rotors (C D) formed conveyor cell in the housing. The cell is then pushed through the following piston head (f) separated from the inlet. The air in the cell (E) is now forwarded without reduction until it reaches the output (B) is reached, from where the air with higher absolute pressure is pushed from the pressure area into the incoming cell in order to then be expelled. Some models are equipped with an automatic by-pass valve (G), which limits the pressure difference between inlet and outlet.

*This description does not consider each manufacturer's approach to the technology, but represents a general description that attempts to cover the basic operating principle.

THE DELIVERY PROGRAM FROM EHRLER & BECK INCLUDES THE FOLLOWING SERIES: