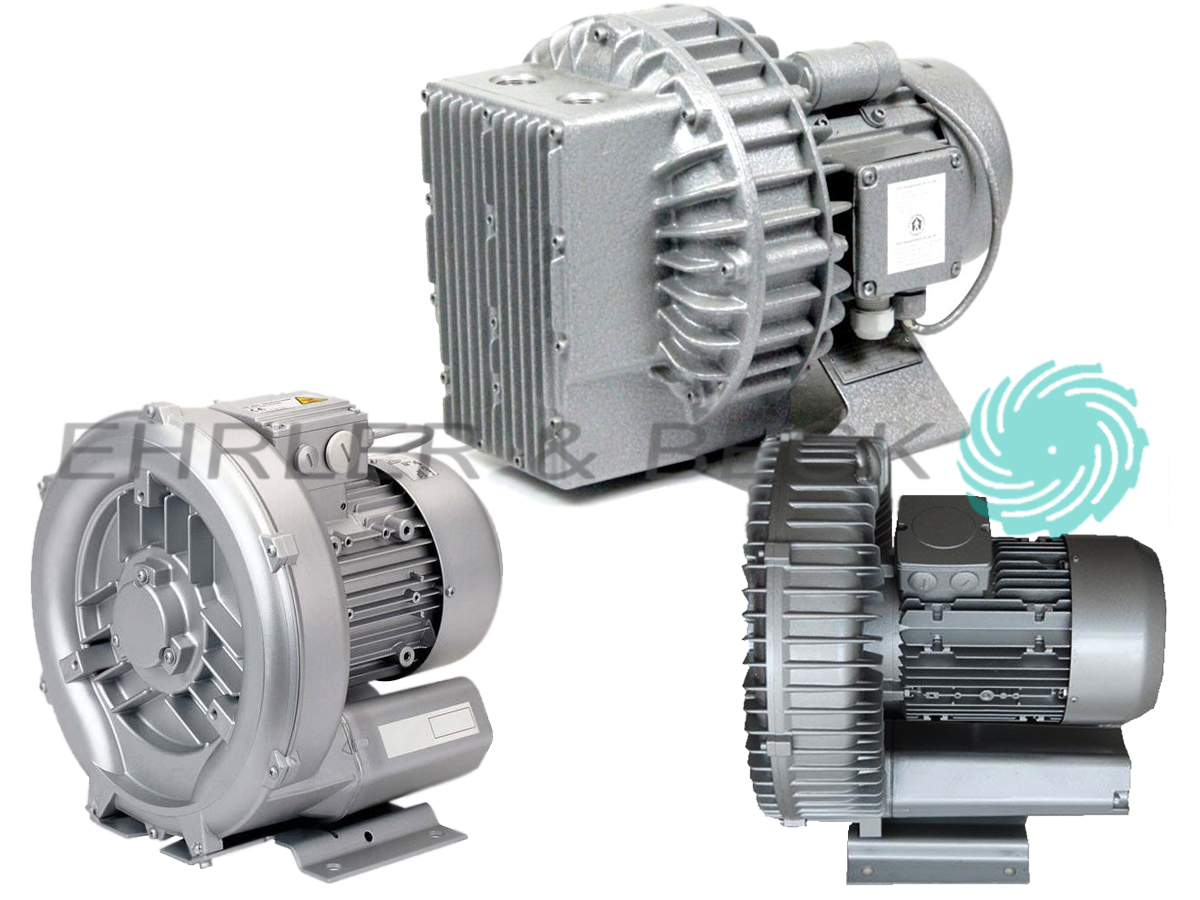

SIDE CHANNEL BLOWERS

Side channel compressors generate low-pulsation blown air due to their internal "multi-stage" compression. The optimal impeller design with curved impeller blades guarantees optimal efficiency. The separation of the compression chambers on both sides of the impeller enables single-stage, double-entry or two-stage, single-entry operation with just one impeller. Intake filter and pressure safety valve are optionally integrated in the patented design of the silencer. The silencers can be varied in length for flexible adaptation to the available installation space.

The advantages at a glance

- low noise

- Virtually maintenance free

- Reliable and durable

- Robust with low weight

- Can be installed in all axis positions

- Variable in the performance range

- Worldwide use (UL/CSA/IEC/EN certified)

- 50/60 Hz voltage range versions

- ATEX

- Speed controllable via external or integrated converter

application areas

- structural drying

- Filling of bags / bottles / silos

- Aeration of sewage treatment plants

- soil remediation

- dental suction

- food degassing

- pond aeration

- gas analysis

- lift and hold

- industrial vacuum cleaner

- plastic industry

- laser printer

- paper processing

- Pneumatic promotion

- Sorting / inserting letters

- textile industry

- packaging industry

- Central vacuum systems

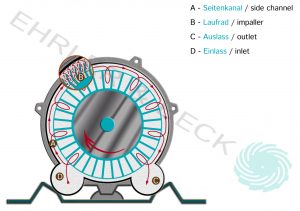

operating principle

Gas escapes via the intake port (D) a. The impeller in some pumps is mounted directly on the motor shaft for non-contact compression, resulting in increased durability. When the gas enters the side channel (A) occurs, the rotating impeller (B) spirally accelerated in direction of rotation. The effect of centrifugal force ensures that the gas in the impellers (B) is accelerated radially outwards and the pressure is increased. With each re-entry into the impeller, kinetic energy is fed back to the impeller along the side channel. The cross-section of the side channel decreases at the interrupter, the gas is scraped off by the impeller and leaves the pump through the outlet opening (C). A high degree of operational safety and a long service life, even with high differential pressures, is guaranteed by the arrangement of the bearings outside the compressor chamber.

* This description does not reflect each manufacturer's approach to the technology, but represents a general description that attempts to include the basic operating principle.

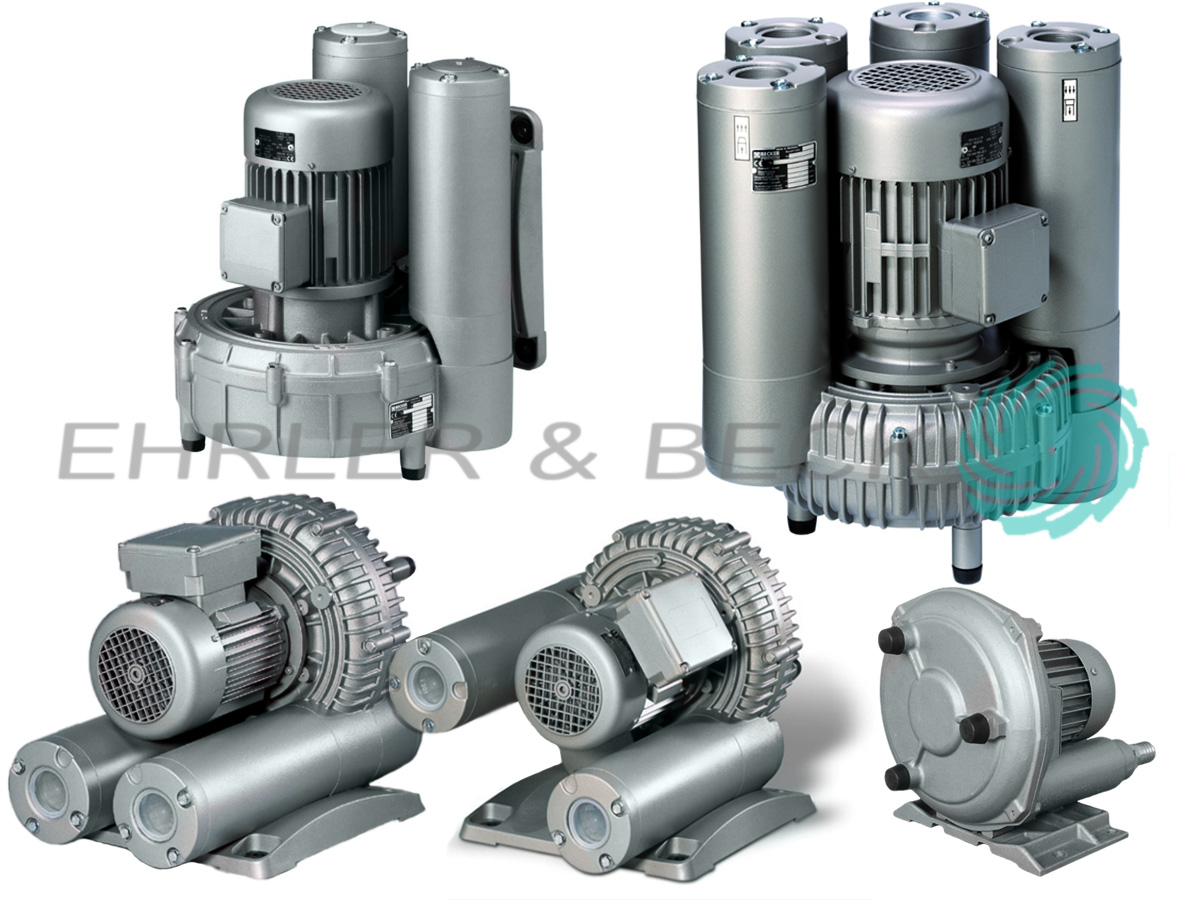

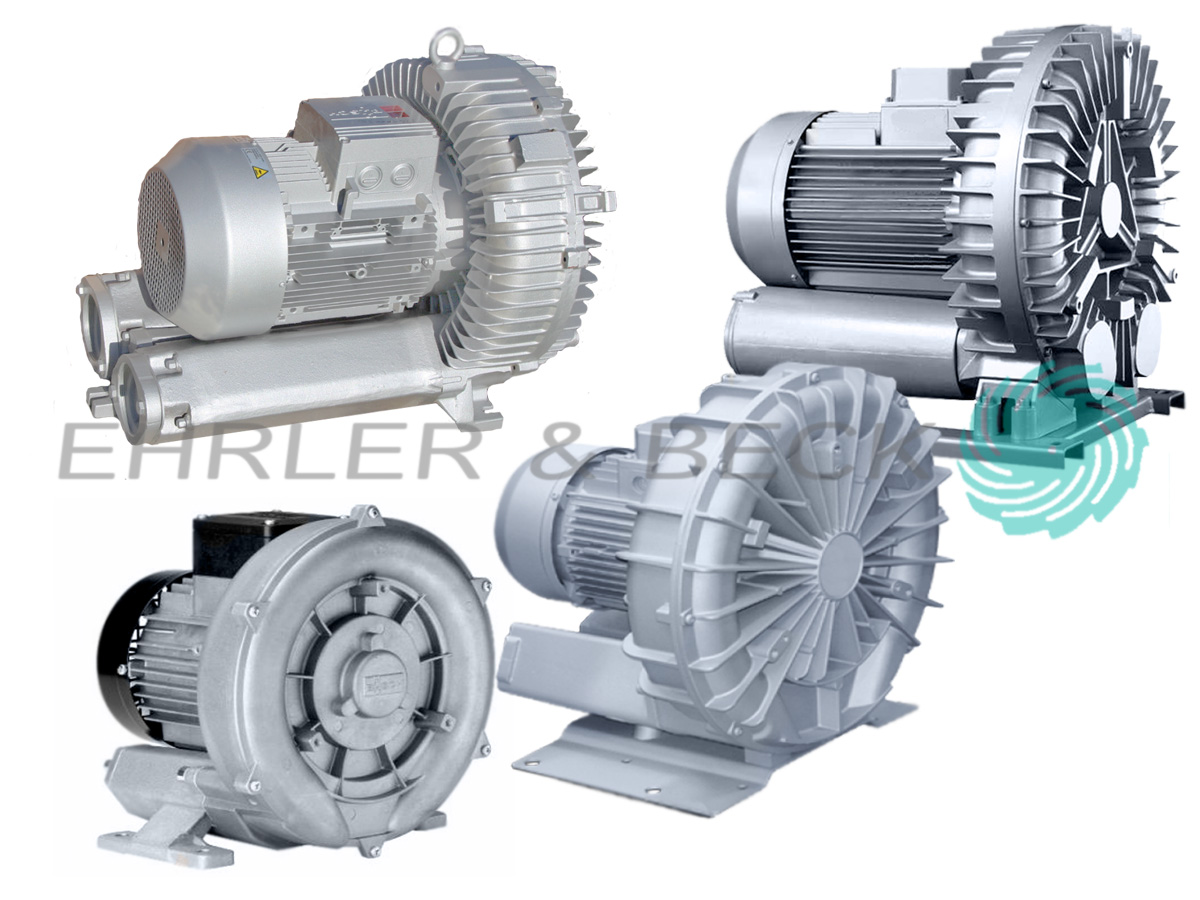

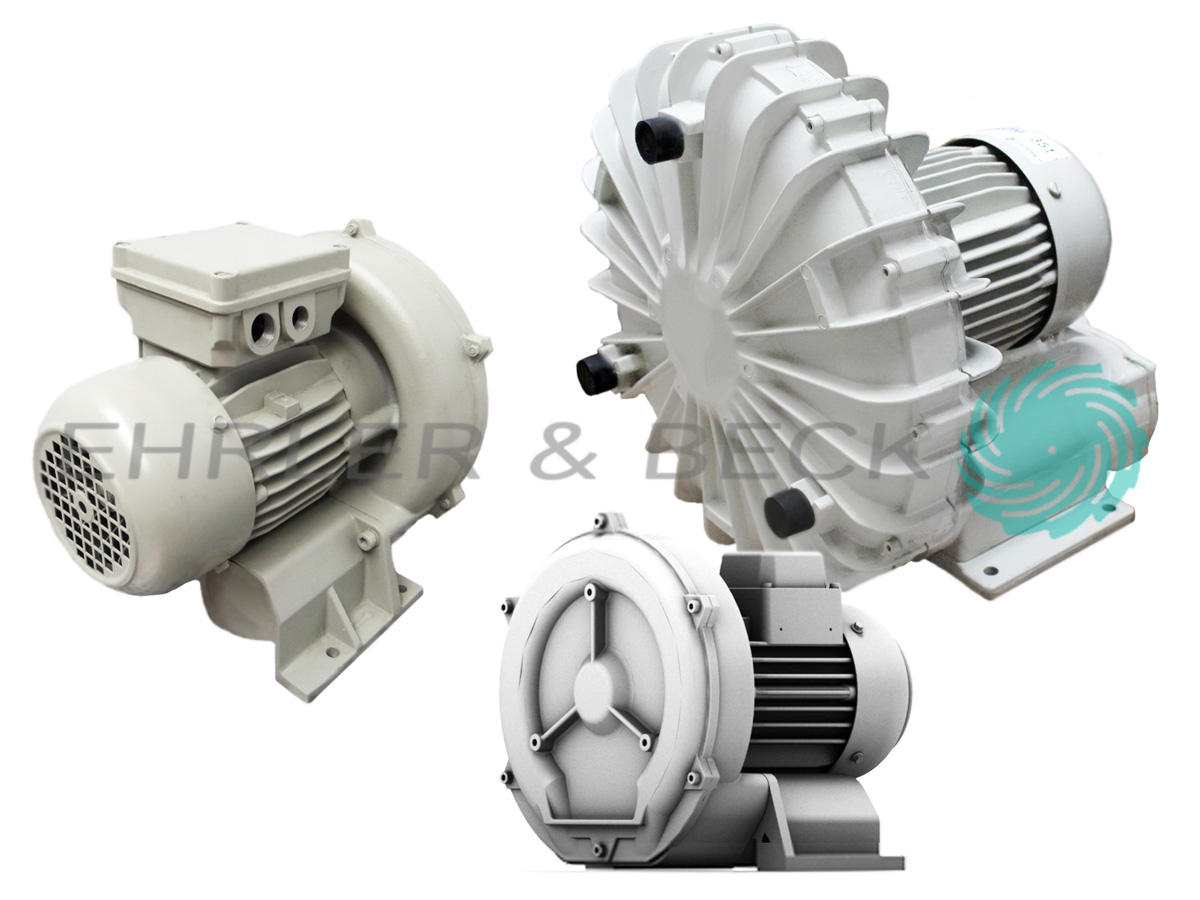

THE DELIVERY PROGRAM FROM EHRLER & BECK INCLUDES THE FOLLOWING SERIES: