LIQUID RING VACUUM PUMPS

Liquid ring vacuum pumps are mainly used in damp and wet work processes due to the use of high-quality materials such as stainless steel and ceramics. In addition, this ensures constant functionality and running properties. These vacuum pumps are more reliable than modular pumps and significantly reduce operating costs.

The advantages at a glance

- Extremely quiet

- Consistent operating characteristics

- High abrasion resistance

- Excellent corrosion resistance

- No deposits

Application examples

Food / luxury food industry

- dairy industry

- central vacuum system

- filtration systems

- Water deaeration in the beverage industry

- food preservation

- seawater desalination

- tobacco humidification

- sugar production

packaging machine industry

- roller machines

- filling and sealing machines

- Filling of beer in PET bottles

- blister machines

ceramic and brick industry

- Ceramic bulk degassing

Other Applications

- water degassing

- groundwater lowering systems

- drying plants

- Blow air in sewage treatment plants

- Extraction of oil residues

- steam turbines and engines

- pit suction

- lifting and handling

- Yarn evaporation in the textile industry

The advantages at a glance

- extremely quiet

- consistent operating characteristics

- high abrasion resistance

- excellent corrosion resistance

- no deposits

Application examples

Food / luxury food industry

- dairy industry

- central vacuum system

- filtration systems

- Water deaeration in the beverage industry

- food preservation

- seawater desalination

- tobacco humidification

- sugar production

packaging machine industry

- roller machines

- filling and sealing machines

- Filling of beer in PET bottles

- blister machines

ceramic and brick industry

- Ceramic bulk degassing

Other Applications

- water degassing

- groundwater lowering systems

- drying plants

- Blow air in sewage treatment plants

- Extraction of oil residues

- steam turbines and engines

- pit suction

- lifting and handling

- Yarn evaporation in the textile industry

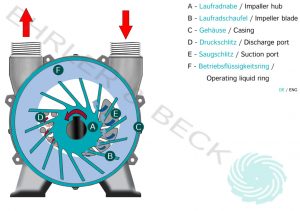

operating principle

The only moving part inside the liquid ring vacuum pump is the eccentrically mounted impeller (A), which moves without contact inside the pump housing (C) rotates. The operating liquid ring (f) seals the impeller blades (B) among themselves. Gas reaches the vane cells through the suction slit (E). In order to maintain the stability of the liquid ring with the gas, liquid is continuously sucked into the suction chamber and fed through the pressure slots (D) expelled again. Due to the eccentric arrangement of the impeller, gas is compressed within one full revolution, i.e. for the chamber between the blades (B) of the wheels. Liquid must be constantly supplied to the pumps for stable operation. For this reason, the liquid ring vacuum pumps of the L-BL / L-BV series are equipped as a system solution with circulation units as standard, through which the operating liquid discharged on the pressure side is fed back to the pump. The pump can therefore work with a significantly reduced liquid supply.

*The description does not take into account each manufacturer's approach to the technology, but represents a general description that attempts to include the basic principle of operation.

THE DELIVERY PROGRAM FROM EHRLER & BECK INCLUDES THE FOLLOWING SERIES: