ROTARY VANE COMPRESSORS, OIL FREE

Through simple design and with only a wave and equipped with a direct drive, robust and durable compressors are created low maintenance and upkeep costs. These vacuum pumps operate completely oil-free; the individual chambers are through long-lived Sliders separated from each other. Most models have integrated intake filters and control valves. These compressors can be combined with otheraccessories be equipped. The compact cover hood guarantees low noise emissions and low heat emissions. With optional corrosion protection, these compressors are also suitable to extract moist air.

The advantages at a glance

- Low noise level

- Eco-friendly, oil-free

- Robust and economical

- Long downtimes

- Low maintenance

- Easy to use

- Reliable and resilient

- Comprehensive range of accessories

Application examples

industry in general

- Pick up and place

- handling technique

printing industry

- printing machines

- print finishing machines

Packaging

- packaging machines

timber industry

environmental engineering

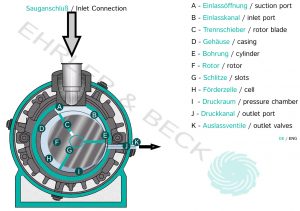

operating principle

An eccentric within the cylindrical housing bore (D) bearing rotor (f) almost touches the above hole (E). In several rotor slots (G) are lamellae (C) or cutting disks that slide along the inner surface of the cylinder. This happens due to the centrifugal force created by the rotation of the rotor. A conveyor cell (H), whose volume changes continuously during rotation. When the rear louver closes the end of the intake port (B) has been reached, the cell reaches its maximum air volume. As the row moves further away from the suction channel, the volume decreases. Therefore, the air is compressed and the pressure increases. This continues until the pressure in the cell exceeds the pressure in the pressure chamber (I) and the air then passes through the pressure channel (J) flows out. In some pressure channel models there are outlet valves (K) that prevent the backflow of the exhaust air from flowing into the cell.

* This description does not reflect each manufacturer's approach to the technology, but represents a general description that attempts to include the basic operating principle.

THE DELIVERY PROGRAM FROM EHRLER & BECK INCLUDES THE FOLLOWING SERIES: