SCREW VACUUM PUMPS

Directly driven Thanks to an integrated frequency controller, these pumps do not require any drive shafts. The area where the units work is 100% oil free. The integrated speed controller optimized the energy applied by matching the inflow flow with the actual demand. This procedure generates a high level of efficiency and minimizes energy consumption. Intake air remains the entire timepulsation free. Various accessories such as suction filters, non-return valves, sound absorber and also filing air and drainage systems, are included in the complete soundproofing structure.

The advantages at a glance

- Running dry

- Reliable and economical

- Single stage high vacuum

- Low noise level

- Application specific options

- Long downtimes

- Low maintenance

- Rinse and CIP capable

- Not sensitive to liquid hammer

- Good water vapor tolerance

- Short evacuation times

Application examples

Chemical industry

- dry

- Distill

- Rectify

- Evaporate

- Degas

- Cool

Surface technology / electronics

- vacuum metallurgy

General Applications

- extraction systems

- drying

- coating

- vacuum metallurgy

- cleaning

- industrial furnaces

Pneumatic promotion

- central vacuum systems

Research / Laboratory

- Different process

Packaging

- food processing and packaging

- Centralized vacuum systems for non-food packaging

The advantages at a glance

- running dry

- reliable and economical

- single stage high vacuum

- low noise level

- application-specific options

- long downtimes

- low maintenance

- Rinse and CIP capable

- not sensitive to liquid hammer

- good water vapor tolerance

- short evacuation times

Application examples

Chemical industry

- dry

- Distill

- Rectify

- Evaporate

- Degas

- Cool

Surface technology / electronics

- vacuum metallurgy

General Applications

- extraction systems

- drying

- coating

- vacuum metallurgy

- cleaning

- industrial furnaces

Pneumatic promotion

- central vacuum systems

Research / Laboratory

- Different process

Packaging

- food processing and packaging

- Centralized vacuum systems for non-food packaging

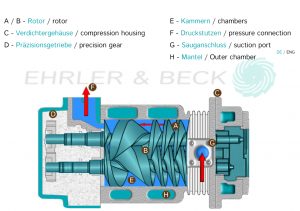

operating principle

Inside the pump housing, without contact and with very narrow gaps, two parallel helical rotors rotate (AWAY) in the opposite direction. The rotation is controlled by a precision gear (D) synchronized. A screw rotor has a left-hand thread, another has a right-hand thread. compression chambers (E) are formed with the compressor housing by the special shape of the screw rotors. Due to the opposite rotation of the two screws, the one with the suction connection (G) connected chamber increases and transports the gas into the compression chamber. The arrow indicates the axial displacement of the chambers in the housing. On the pressure side, the chamber is pushed against the axial housing wall and the volume is reduced until the face of the screw opens the pressure channel and the pre-compressed gas flows through the pressure port (f) is discharged. Cooling is provided by water chambers (H), additional cooling gas and similar methods, depending on the manufacturer and the size of the pump.

*This description does not consider each manufacturer's approach to the technology, but represents a general description that attempts to cover the basic operating principle.

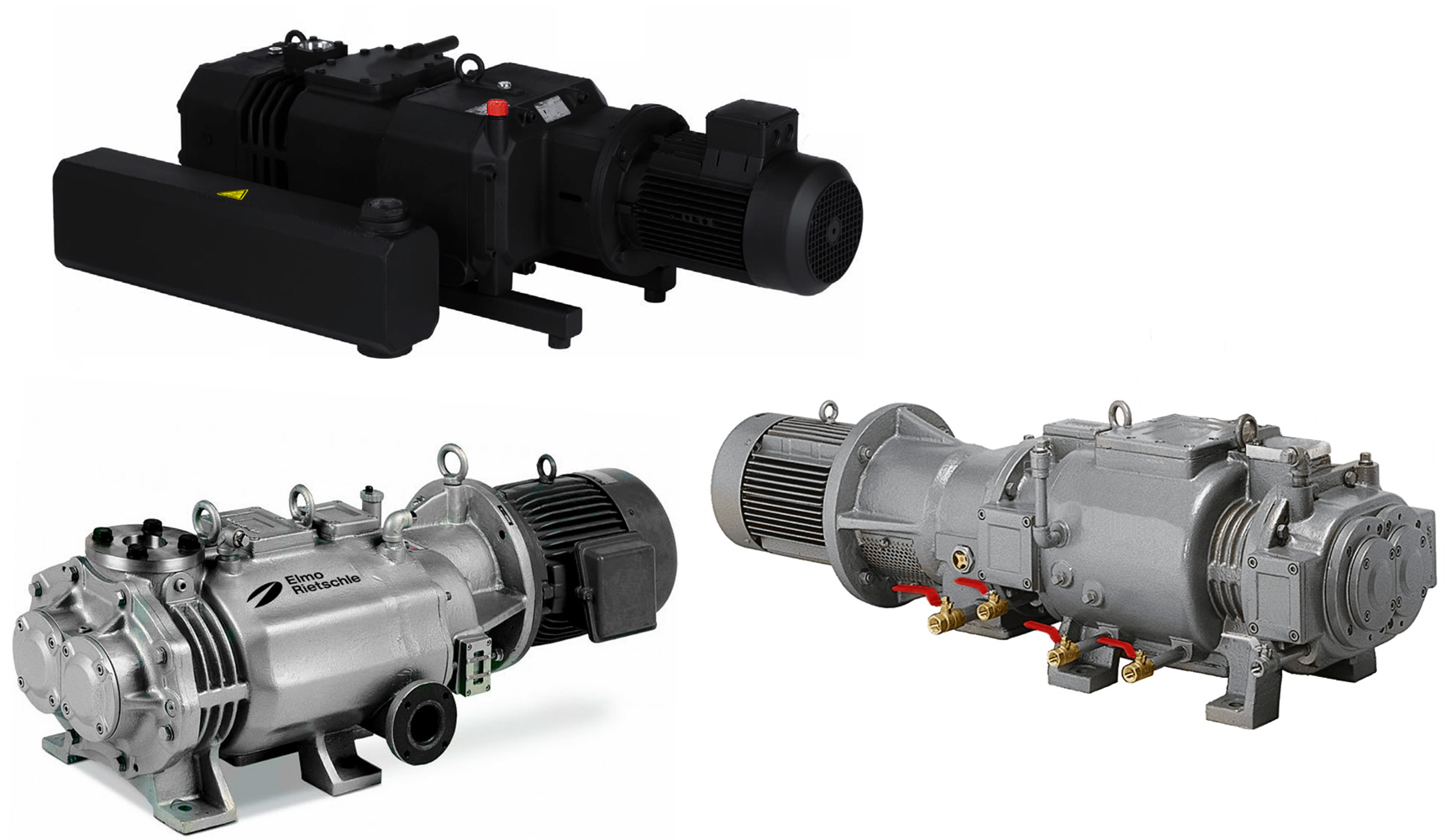

THE DELIVERY PROGRAM FROM EHRLER & BECK INCLUDES THE FOLLOWING SERIES: